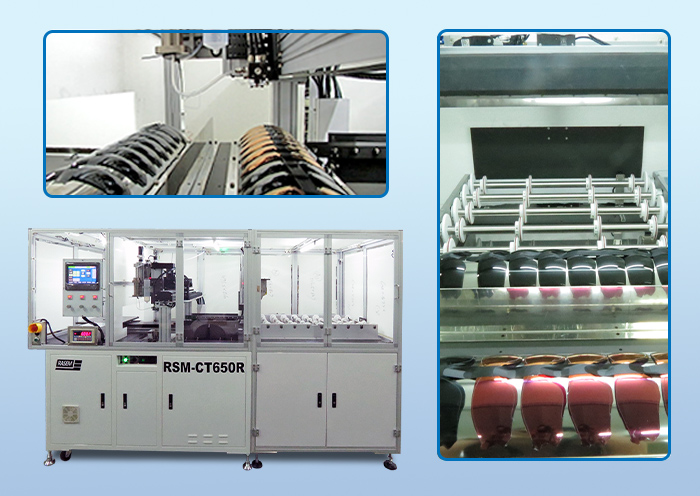

RSM-CT650R

Introduction

This system uses PLC (Programmable Language Controller) and human-machine interface operating system to control the action of the four-axis mechanism, respectively control the spraying mechanism and the quantitative feeding mechanism. The exhaust circulation of the system itself can reduce the floating of impurities inside the machine and provide heat dissipation.

Details

Spraying Agency

- Enclosed spray space to reduce contamination.

- A wide range of applications, such as AR, AG, Hard Coating can be uniformly coated.

- Easy to operate, it adopts two-fluid nozzle with low flow and low atomization pressure, and the needle nozzle valve can precisely control the flow rate from 0~50ml/min.

Device Features

- 1. After one-time spraying, one-time baking is enough.

- 2. The equipment can be customized.

- 3. With AG Spray Coater dedicated spray valve and flow control system.

- 4. The largest product can be 2500*1500mm.

- 5. Provide complete equipment expertise and process solutions.

- 6. Provide equipment design changes according to different potion characteristics.

Spesifications

- 1. The glass has no flash point and no bright spot after spraying.

- 2. The hardness effect is the best in the industry, and the RA value is the lowest in the industry.

- 3. The yield rate measured by the industry can reach more than 90%.

- 4. Potion supplier certified and designated as recommended spray equipment.

- 5. It has successively obtained customer certification for mass production introduction.

Related Applications

Mobile phone/tablet/laptop/LCD/vehicle panel, building wall glass, whiteboard glass, explosion-proof glass, etc.